First we got a piece of wood the same height as your frame and cut it to the same length as the frame.

Then we drilled two holes to fit a couple of bolts into (we used 10x100mm bolts).

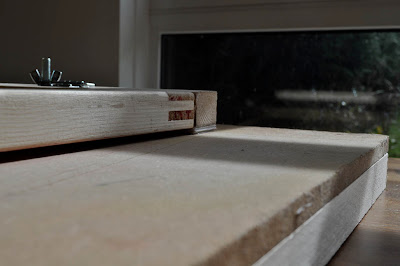

Then with the rest of the strip of wood that we cut earlier, we cut it into batons that we then screwed onto the underside of our base board (flat sheet of mdf). This was to give the whole press more height, and to allow for the depth of the bolt heads.

Then we screwed two hinges (the fancy ones bought last week) to attach the screen to our base. We also screwed one last strip of wood onto the side of the screen to act as a prop keeping the screen up (very useful bit).

Finally we pad the whole frame up by roughly 5mm, to make sure the frame doesn't sit on the base board. Obviously the fabric part of the screen has to be able to stretch down to the base board when pressed with a squeegee but pop back away afterwards.

When padding up the frame you have to do under the two bottom corners and the whole strip of wood with the bolt holes through, and make sure they all match.

Wow that's amazing! You built your own press! Now you need to get him to build a drying rack!

ReplyDeleteexactly! Rather weirdly they seem to have some cute ones at the nursery (in the shape of a caterpillar). I'm quite tempted to get one of them. Very stylish eh? :)

ReplyDelete